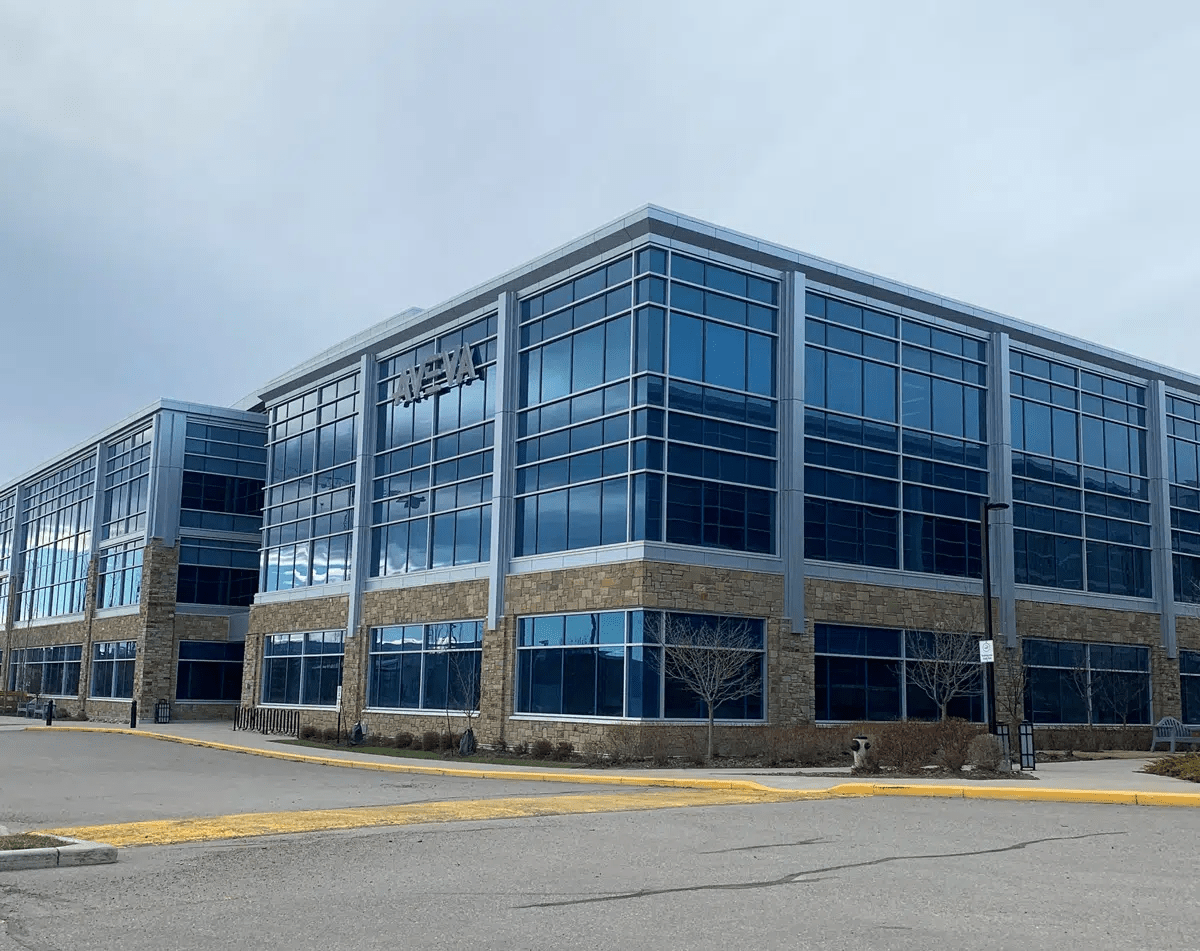

The Importance of Manufacturing Building Security

Manufacturing buildings are more than just structures; they are critical assets that play a vital role in economic prosperity and national security. These facilities process raw materials, produce engines, turbines, and power transmission equipment, manufacture electrical components, and create transportation vehicles. The security of these buildings is paramount, as they often house specialized equipment, valuable intellectual property, and critical operations that, if compromised, could result in significant economic losses and potential threats to public safety.

Prioritizing security in manufacturing environments is crucial for several reasons. First, owners and operators have legal and ethical responsibilities to ensure the safety of their personnel and the protection of their assets. Second, effective security measures significantly impact operational continuity, productivity, and the ability to meet stringent manufacturing schedules. Lastly, maintaining a secure environment safeguards the company's reputation, protects against intellectual property theft, and ensures compliance with industry regulations.

Failing to implement adequate security measures can lead to severe consequences. Manufacturing facilities may face production disruptions, theft of valuable materials or products, industrial espionage, and potential harm to employees. Moreover, security breaches can result in costly legal liabilities, damage to the company's reputation, and loss of competitive advantage in the marketplace.

Physical Access Control Systems

Access control is a fundamental aspect of manufacturing building security. An effective access control system serves as the primary barrier to unauthorized entry, ensuring that only authorized personnel, visitors, and vehicles can enter the facility or specific areas within it. These systems may range from traditional key cards and biometric scanners to advanced multi-factor authentication methods. When selecting an access control system, manufacturers should consider factors such as security level, reliability, scalability, and integration with other security systems. A well-implemented access control system not only restricts unauthorized access but also provides valuable data for monitoring personnel movements and investigating security incidents.

Surveillance and Monitoring

Modern security strategies for manufacturing buildings incorporate high-quality surveillance cameras and advanced monitoring systems. These tools offer continuous surveillance, often enhanced by artificial intelligence for real-time threat detection. Security cameras provide visual documentation of activities throughout the facility, which can be crucial in preventing theft, monitoring production areas for safety compliance, and investigating incidents. Remote monitoring capabilities allow security personnel to maintain vigilance even when not physically present on-site. The integration of video analytics can help identify unusual patterns or behaviors, enhancing the overall security posture of the facility.

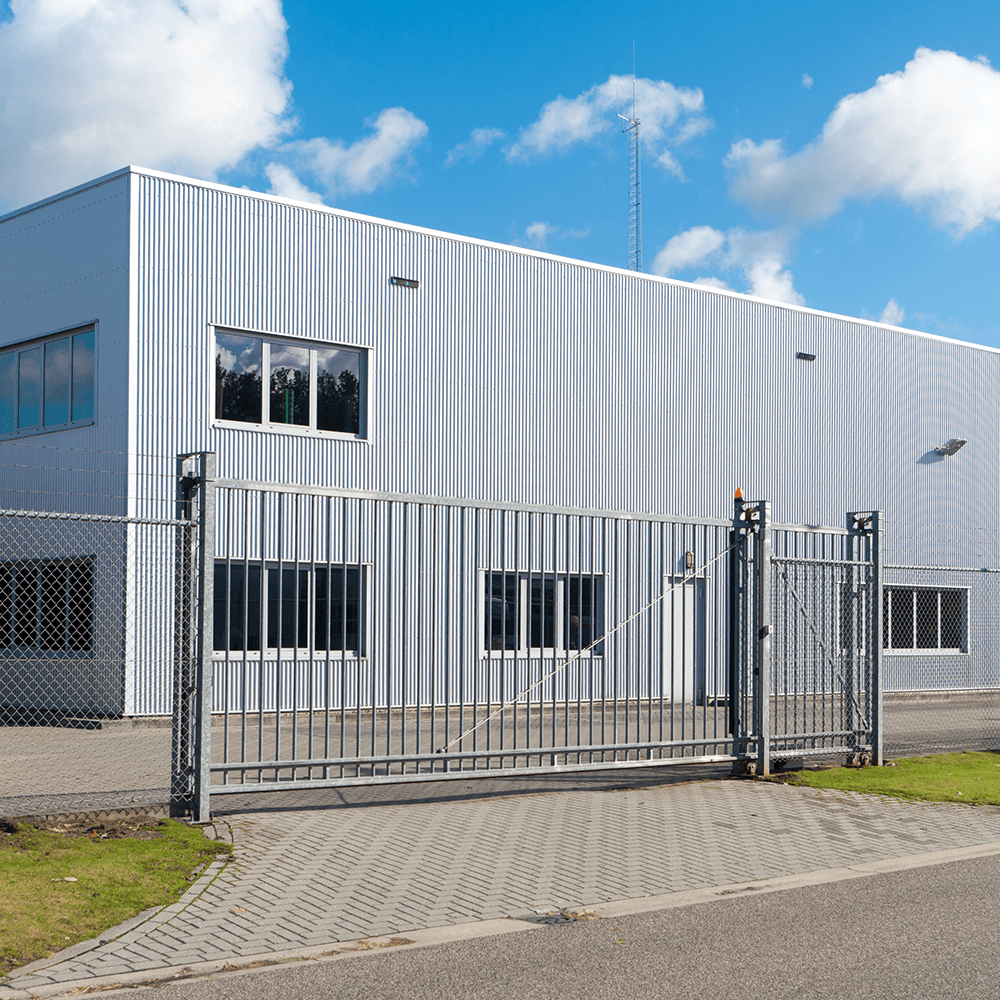

Perimeter Security

Securing the perimeter of a manufacturing facility is critical to preventing unauthorized access and protecting assets. This may include robust fencing, vehicle barriers, security lighting, and intrusion detection systems. Key areas to focus on include entry points, loading docks, and any areas where the facility interfaces with public spaces. Regular inspections and maintenance of perimeter security elements ensure their continued effectiveness. Additionally, clear zones around the perimeter can improve visibility and deter potential intruders.

Employee and Visitor Management

Human factors play a significant role in the security of manufacturing buildings. Implementing thorough background checks for employees, contractors, and frequent visitors is essential. Security awareness training should be provided to all personnel, covering topics such as identifying and reporting suspicious activities, proper handling of sensitive information, and adherence to security protocols. A well-designed visitor management system ensures that all non-employees are properly screened, escorted, and monitored while on the premises. This may include issuing temporary badges, maintaining visitor logs, and restricting access to sensitive areas of the facility.

AI-Enhanced Security Systems

Artificial Intelligence has transformed security systems in manufacturing facilities. AI can be integrated into various security components, from access control to video surveillance, to enhance threat detection and response capabilities. For example, AI-powered video analytics can identify unusual behavior patterns, detect unauthorized access attempts, and even recognize specific individuals. These advanced systems can significantly reduce false alarms and allow security personnel to focus on genuine threats, improving overall security efficiency.

Industrial Internet of Things (IIoT) for Security

The Industrial Internet of Things (IIoT) offers new opportunities for enhancing manufacturing building security. IIoT devices can be used to monitor critical equipment, environmental conditions, and security parameters throughout the facility. By collecting and analyzing data from various sensors and connected devices, manufacturers can gain real-time insights into their security status, predict potential issues before they occur, and respond more quickly to security incidents. However, it's crucial to ensure that these IIoT devices themselves are secured against potential cyber threats.

Regular Security Assessments

Security in manufacturing environments is not a one-time effort but requires persistent management and continual enhancement. Regular security assessments are indispensable for identifying potential vulnerabilities and areas for improvement. These assessments should cover both physical and cyber aspects of security and be conducted at least annually or whenever significant changes occur in the facility's operations or the threat landscape. The results of these assessments should drive updates to security policies, procedures, and technologies.

Continuous Improvement and Adaptation

The security landscape for manufacturing facilities is constantly evolving, with new threats emerging regularly. Therefore, a commitment to continuous improvement is essential. This involves staying informed about the latest security technologies and threat intelligence, regularly updating security protocols, and providing ongoing training for employees. Manufacturers should also be prepared to adapt their security measures in response to changing operational needs, such as the introduction of new production lines or shifts in the global supply chain.